Expansion Joints

Pipe expansion joints are flexible components used in piping systems to absorb thermal expansion, vibration, and movement. These joints help prevent stress and damage to pipes, ensuring the system remains intact and functional. They are commonly used in industries such as power generation, chemical processing, and HVAC systems, where temperature variations and mechanical forces can affect the pipeline’s integrity.

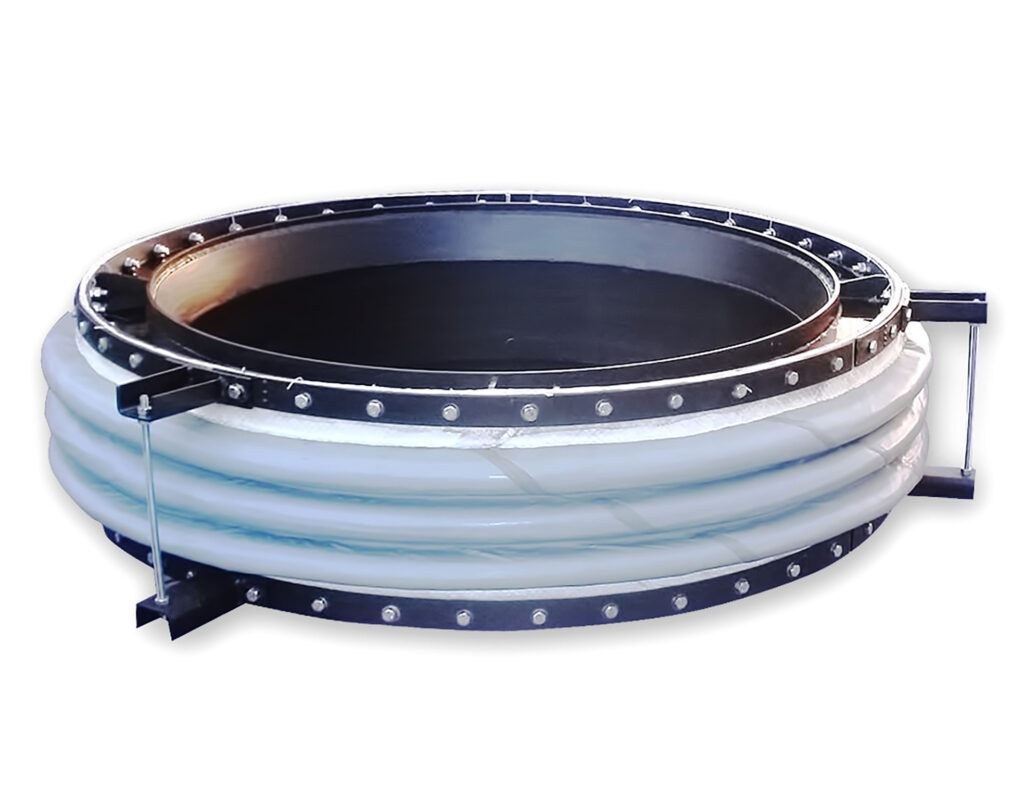

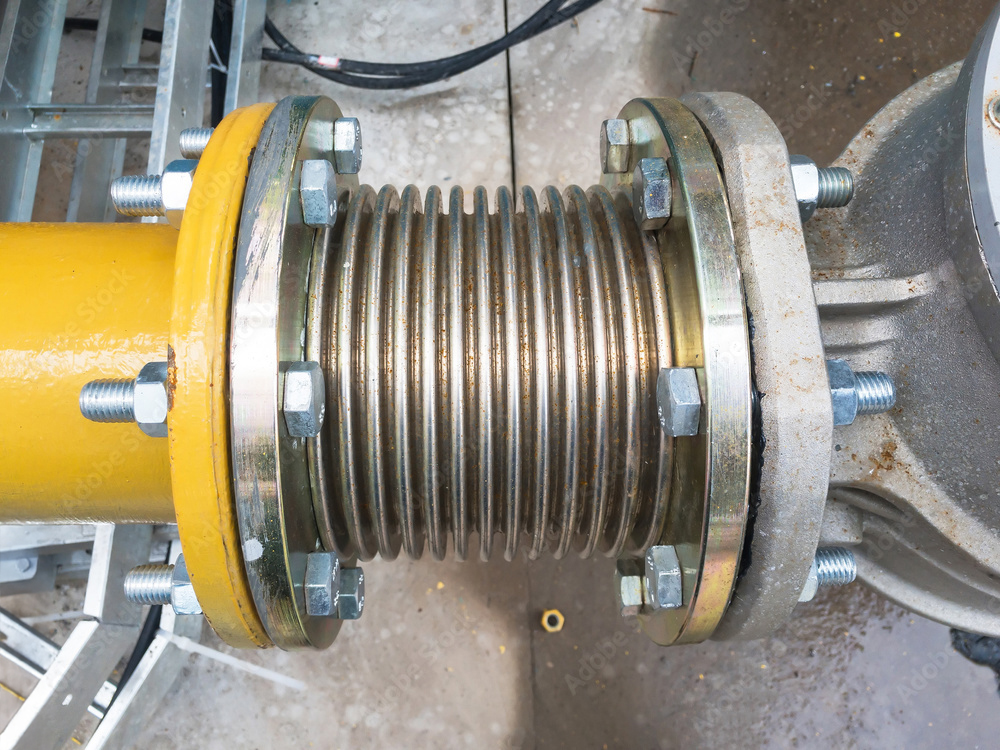

Expansion joints come in various types, including metal, rubber, and fabric, each designed for specific applications. Metal expansion joints are typically used for high-pressure and high-temperature environments, while rubber expansion joints offer flexibility and resistance to corrosion. Fabric expansion joints are ideal for systems that require lightweight solutions and adaptability to complex movements. The selection of the right type depends on factors such as pressure, temperature, and the type of media flowing through the pipeline.

By accommodating movement, pipe expansion joints reduce maintenance costs and extend the lifespan of piping systems. They help in minimizing noise and vibration, enhancing the overall efficiency of industrial operations. Proper installation and regular inspection are essential to ensure their optimal performance and prevent failures. These joints play a crucial role in maintaining the safety and reliability of piping networks across various industries.