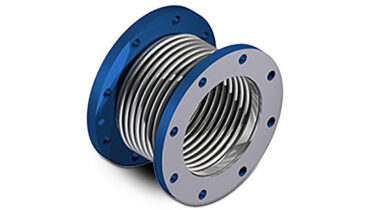

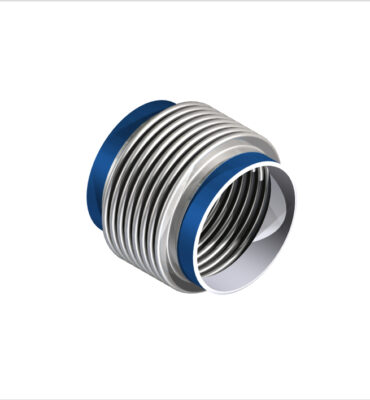

Axial Expansion Joints

1. Brief Description

• Axial Expansion Joints are mechanical devices designed to absorb axial movements (linear expansion and contraction) in piping systems.

• They consist of a flexible bellows element that compresses or extends in response to changes in temperature, pressure, or mechanical forces.

• Commonly used to manage thermal expansion and prevent damage to piping, equipment, and structures.

2. Main Features

• Absorbs axial movement in a single line of piping.

• Reduces thermal stresses and eliminates the need for expansion loops.

• Can operate under high pressure and temperature conditions.

• Compact design, making them space-saving and easy to install.

• Optional features like internal liners (to reduce turbulence and wear) or external covers (for protection).

• Designed for long service life with minimal maintenance.

3. Material of Construction

• Bellows: Stainless steel (grades like SS304, SS316, SS321) for flexibility and corrosion resistance.

• End Connections (Flanges/Weld Ends): Carbon steel, stainless steel, or alloy steel.

• Liners (if included): Stainless steel or other alloys to withstand high velocities and abrasive media.

• Covers (if included): Carbon steel or stainless steel for external protection.

4. Applications

• Power generation (steam, hot water, and gas pipelines).

• Petrochemical and chemical plants (fluid transfer lines).

• Oil and gas industry (pipelines and refineries).

• HVAC systems for thermal movement control.

• Desalination plants and water treatment facilities.

• Pulp and paper industries.

5. Size Range

• Typically available in sizes ranging from 1 inch (25 mm) to 120 inches (3,000 mm) in diameter.

• Custom sizes and configurations can be designed for specific project requirements.